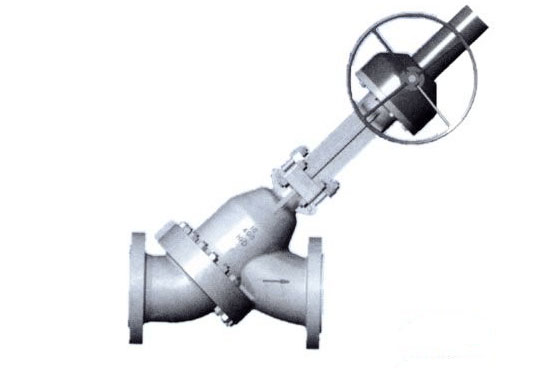

MAIN FEATURES: It refers to a slurry valve with its stem and passageway forming a certain angle, and its seat sealing face and inlet and outlet passageways forming a certain angle. It is divided into left and right parts with a seat between them. The bolt connecting the two parts can be dissembled to replace the valve seat. An anti-washing and anticorrosion protection plate is set in the cavity of the valve body. This kind of slurry valve hardly changes the flowing direction. The valves are widely used in chemical fertilizer, mining, metallurgy, aluminum oxide and other industries. Design Features Design standard as per: BS1873¡¢GB/T 12235. Smooth fluid passageway and small fluid resistance. The sealing adopts spherical seal, the surface of which is line connecting. High abrasion-resisting and erosion-proof. The valve is designed as a back seat sealing structure. Full Stellite or Tungsten carbide overlay seat sealing surface. Use flexible and woven graphite collaboration type packing. Product Range Body material: carbon steel, stainless steel, alloy steel Nominal diameter:1/2"¡«24"£¨DN15~DN600£© Pressure range:Class150¡«2500£¨PN10~PN420£© End connection: RF, RTJ, BW Working temperature:-29¡æ¡«560¡æ Operation: handwheel, gear box, electric, etc.